Do you remember that I was considering making a "French Couture jacket"? It was ages ago. You've probably forgotten the whole thing. I armed myself with Claire Schaefer's book, cranberry wool tweed woven by my mom, bronze buttons and some foufy mohair trim. So what the hell happened.....where to begin?

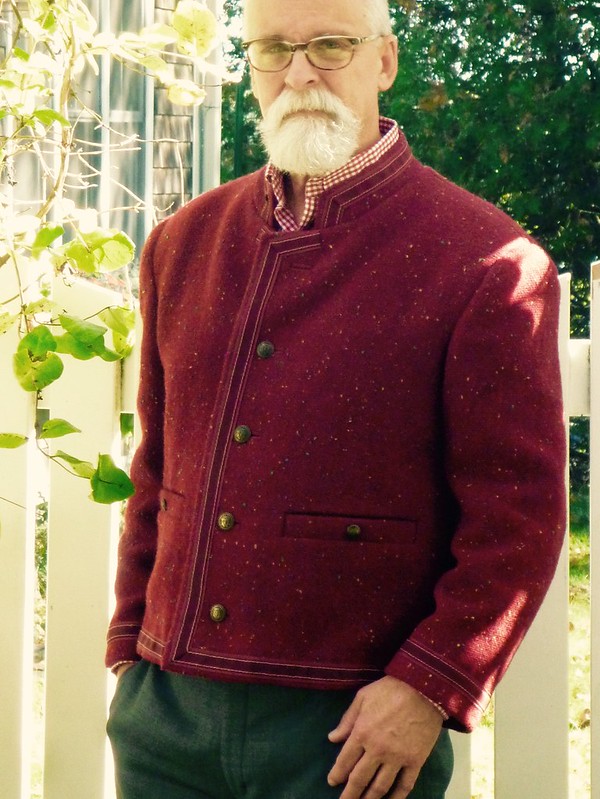

The general consensus from you, my readers, was that the froufrou trim had to go. I'm just not Pharrell Williams enough to pull that look off. On me, it would be "ladies who lunch" gone WAY wrong. So I went back to the trim stores in NYC and settled on a burgundy faux suede with contrast edge stitching. Decidedly simpler but not flexible enough to conform to my pattern's curved collar and lower front edges. Rather than fight with the trim to make it curve, something it was NEVER going to do, I squared off the collar and jacket fronts. In sewing, as in life, you have to pick your battles.

Overall, the pattern was fairly easy to fit. I increased the width of the collar (there just wasn't enough room for the trim), shortened the body by about 4" and added extra curve to the upper back (the dowager's hump adjustment, ouch! Like that doesn't make me feel ancient). Then the real games began.

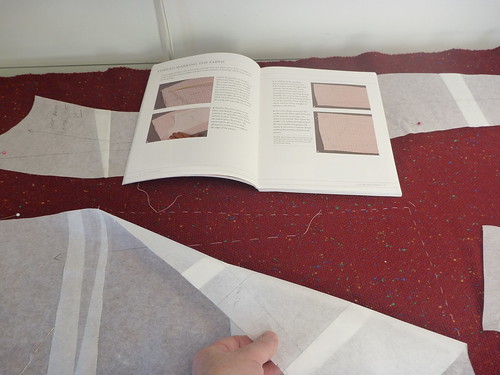

Straight up....if you're looking for the most complicated and time consuming way to construct a garment, this "Couture jacket" will be right up your alley. None of it is particularly difficult....cumbersome is the word that comes to mind. Here I'm cutting off all the pattern seam allowances to start.

Then the pattern shapes are thread traced onto the fabric. There is, of course, a very specific way in which this is done. Thankfully, Schaefer's book is well illustrated. The grain line, notches and any other marks are also marked with thread. Get ready to use a huge amount of cotton basting thread!

Each thread traced piece is on a rectangle of fabric. I swear, the real "luxury" of this construction method is the shear waste of precious fabric that ensues. The fabric gets handled extensively, so I ran all the cut edges through my serger to prevent raveling.

This is about as far as I got sticking to Claire Schaefer's directions. I started to veer off on my own course... more tailored jacket, less floppy cardigan.

I'm sure Coco rolled over in her grave on this one. I interfaced my jacket fronts with a lightweight hair canvas. The "couture jacket" has just the tiniest strip of silk organza selvedge caught in the front edge openings. I also stabilized the shoulder seam with a semi-bias strip of lining material. That's a Roberto Cabrera thing.

Veering even further of course, I wanted welt pockets and bound buttonholes. Not the patch pockets and handworked buttonholes that are the hallmarks of the couture jacket. Oh, and that "Coco-ism". -- "No button without a buttonhole". Forget that!

I don't know about you, but I always like to practice the tricky bits before I launch into something that has the potential of ruining a project. So....

This is a mock up welt pocket that I made with left over scraps. I used Edna Bishop's method. She calls it a "regulation welt pocket". It's surprisingly simple and straightforward once you get up the nerve to start slashing your fabric! For this jacket, I needed to prove to myself that it was going to be possible, considering the bulk of the fabric. I tried to reduce bulk in every way possible.

As luck would have it, making the pocket was entirely possible. The welt is lined with silk charmeuse to reduce its thickness, and there's some serging that will never be visible to keep some seams flatter. So the welt pockets are a go.

I also made a trial bound buttonhole. The welt is the reverse side of my silk charmeuse beefed up with a scrap of Fashion Sewing Supply's Pro-weft Supreme fusible. Reassured that these features are indeed possible, it was full steam ahead.

A piece of silk organza was used as a reinforcement for the welt opening.

The pocket in process. I baste a lot! But it's always time well spent.

Here is the finished pocket (a success) , and the beginning of a MAJOR screw-up. Maybe you see it. I positioned the welt for the second buttonhole on the WRONG side of the jacket. I blissfully followed Laura Mae's fabulous bound buttonhole tutorial (here), marked, stitched, cut open and flipped everything to the....

WTF have I done moment!!!!

Once my blood pressure was back under control, I set about correcting the mess I'd made. I positioned a new welt piece onto the outside of the jacket (where it should have been in the first place) and restitched everything directly over my original stitching. I then very carefully cut the incorrect welt away as close to the stitching as I could get. With tweezers I was able to remove any remaining fibers. Disaster averted. The buttonhole may be a touch smaller than the rest, but I don't think anyone else would notice. Fortunately, there were no other screw ups.

Arcane construction becomes the norm. Mon Dieu! I quite honestly can't remember how I attached the sleeves, but somehow it happened.

But I've blabbed on long enough. If you've stayed with me this far, scroll down through more "in process" pics to see the final result.

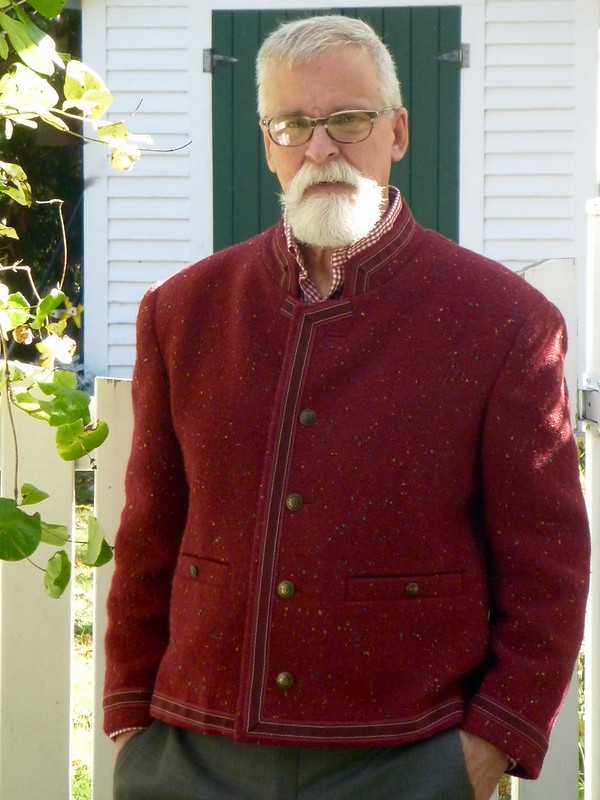

I wore this outfit to host a rehearsal dinner for my son's wedding in October. By then, all the complexities and frustrations of constructing the jacket were a thing of the past, and I just enjoyed wearing it. It truly turned out to be exactly what I wanted. My idea, my execution. A way to honor my mom's artistry and craftsmanship. A little bit French inspired (without the "Ladies Who Lunch" vibe), a little military, a little tyrolian, tailored (but not overly), with a hard to describe sensation of wearing something truly special.

As always, I am so grateful for the support and inspiration I receive from the sewing community. I've sort of fallen off the blog bandwagon a bit, but I still have projects to share. Be well, and happy sewing!