So I've officially taken the plunge.

This will be my guide. I think it's safe to say that this book is considered the bible of kiltmaking. It's a little on the daunting side. The book opens with a series of color plates showing "good kilt" next to "bad kilt". Good kilt length / bad kilt, too short . Good stitching, invisible / bad kilt, stitches too large. Good kilt, stripes straight / bad kilt, stripes wandering. It's hard not to feel defeated before even starting! This lady sets the bar high.

In addition to this book I've also joined an online forum called "X Marks the Scot". Barbara Tewksbury, author of the book, actively participates in the forum. I've already posted several questions and she has chimed in on all of them, sometimes at great length. I've appreciated both her expertise and willingness to explain things in a supportive way. That doesn't always happen in online forums, where some members love nothing more than to pontificate on and on, and never answer the question.

But, I'm getting ahead of myself.

I spent days playing around with possible pleating styles. Yes, days! Without going too deep into the weeds, there are two types of pleating. Pleating "to the stripe" (also called military pleating), and pleating "to the sett" (in which the tartan is reproduced in the pleats). In military pleating the same stripe is centered in the pleats worked across the back of the kilt. My tartan is one of the more simple weaves, made up of only 3 colors. There are really only two possibilities for pleating to the stripe IMO. The yellow stripe centered between the black squares, and the red stripe through the yellow. I sort of approximated them in the photo above.

In the end I rejected both of them. Pleating to the yellow stripe created a very somber, to my eye "muddy", look. It took on almost a greenish cast.

However, it would have produced bright flashes of color when the pleats moved. Lots of drama, but a little too risky for a first (and most likely the only) kilt I will ever make for myself.

Pleating to the red stripe created a very golden yellow kilt. Pretty, but would I love it forever? These are the kinds of quandaries that can keep a man up at night, especially considering the cost of the materials and the amount of labor involved.

In the end I decided that pleating to the sett was the way to go. The pleats in the back will reproduce the tartan, giving the kilt the same appearance all the way around. In other words, I'm taking the safe route.

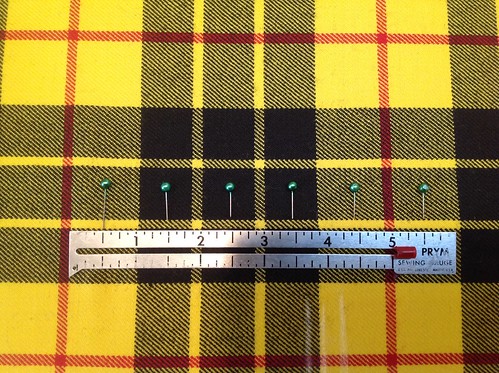

Here I've broken the weave down into the sections that will become the pleats. Each pleat will be 1" wide with a stripe or color border centered in each pleat.

Here I've pinned the pleats into place. The sett of my tartan is actually quite small. Each total repeat of the plaid is only 5". Why does this matter? It makes the depth of each pleat quite shallow. That would be fine if I had a limited amount of fabric to work with, but I have "the whole nine yards!" I definitely don't want a skimpy kilt, so I've decided that each pleat will encorporate two whole repeats of the tartan. Yet another decision that kept me awake at night!

Days of deliberation and not one stitch made! Next time I hope to have made some real progress.